Soft ENIG Process

- Gold plating process for FPCB

- Can implement ultra-fine circuit

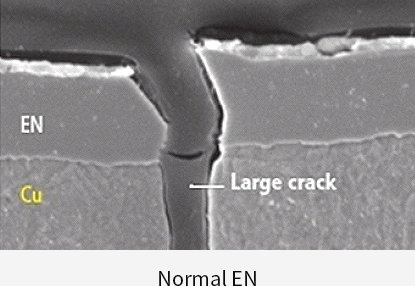

- Excellent folding endurance

- Reduce nickel cracks

HOME

HOMEFinal Surface Treatment The process used for the final treatment of electronic materials such as PCB and semi-conductor. It mainly uses chemical materials such as gold, silver, and palladium for jewelry plating.

Soft ENIG Process

ENEPIG Process

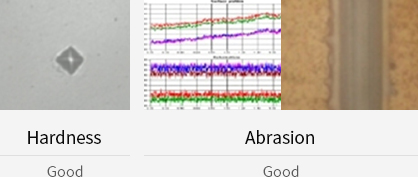

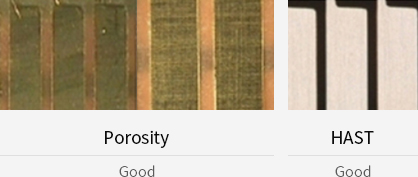

Soft ENIG Process : CF300-10 series / MIKO series

Features

Pretreatment

Soft EN : CF300-10 series

Immersion Gold :

Miko series

After 50 cycle-bending

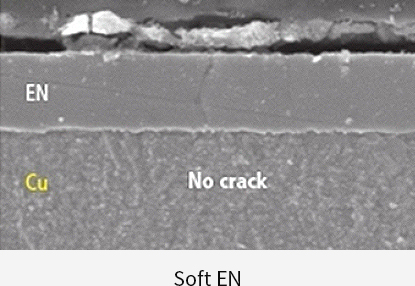

Pd-P(ELP series) or Pure Pd(ZEP series) ENEPIG Process

Features

Plating process

Electrolytic Gold Process : HG300 & SAU10 series

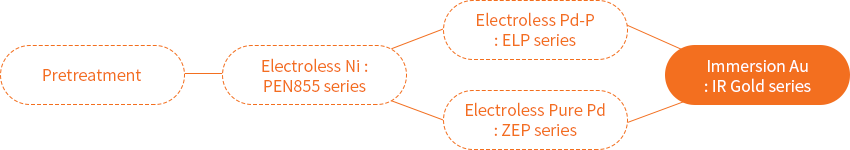

Hard gold process features

Plating process

Cleaner

Etching

Acid Dip

Bright Ni

Acid Dip

Au Str.

Au

Soft gold process Features