Process / Display

For chemical materials used in the process of PCB production and electronic components and materials, we hold various products from stripper used for dry film to flux cleaner.

DR Series

- Diverse strippers that match with different characteristics of customers’ products

- Quick stripping effect and high transference number

SE Series

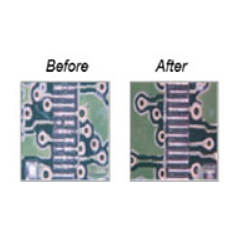

- Able to form uniform copper roughness

- Secure high transference number by improving D/F and PSR adhesion

Gold Recover

- Remove pollutants on the gold surface after surface treatment

- Outstanding pollutant cleaning power compared to competitive products

Cleaner

- Two types of deflux cleaner: aqueous or solvent base

- Remove dust from the equipment to reduce defect rate

- Supply an eco-friendly product without hazardous substances such as methanol

DFR Stripper : DR series

-

For MSAP/SAP Package MSAP/SAP DR-56

- Very small chip size : suitable for Fine Pitch, Chip size : max. 1mm

- Good penetration, no residue ㅣ Little Foam

- High stripping speed, Strip time : max. 2min @ DFR 29 um\

- Cu damage free, Cu E/R : max. 0.01um/min

-

For tenting KOH/NaOH type DR78, DR79 / DR11

- Wastewater treatment with low COD

- Excellent anti-oxidation of copper surface

-

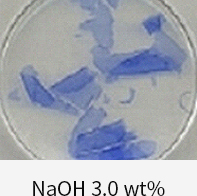

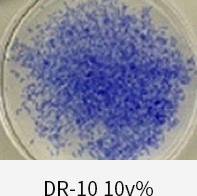

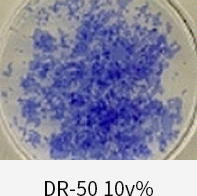

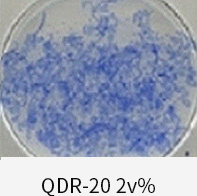

Amine type DR10 / DR50 / QDR20 / DR12

- variable B.P and particle size that match customer's requirements

- Applicable to AU plating + OSP / No effects on EMC adhesion

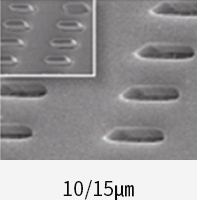

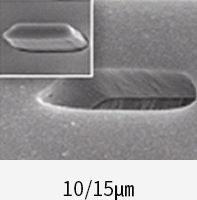

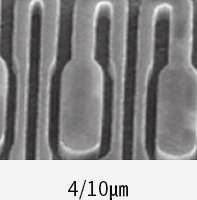

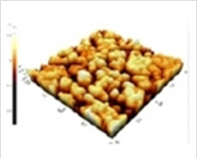

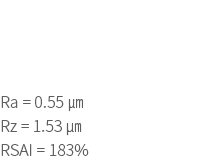

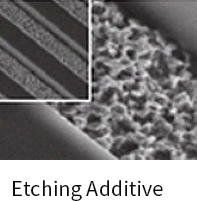

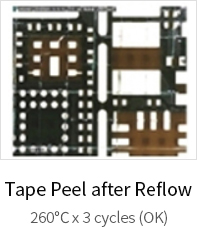

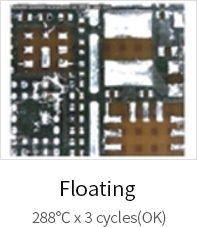

Cu Etching Additives as DFR & PSR Pretreatment for Fine Uniform Roughness : GMZ-20

-

Features

- Etchant based with H2 SO4 / H2O2 | Pretreatment for DFR & PSR | Obtaining fine roughness by multi-functional agents

-

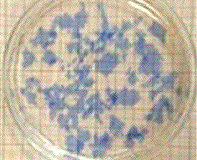

Gold Surface Cleaner : Gold Recover 400 (Acid type) ㅣ 500 (Alkali type)

-

Features

- Improvement of solderability and wire bondability on contaminated gold surface

- No attacks on EMI shield film, SUS stiffener, silk screen ink, SR etc.

- Improving solderability and wire bondability by cleaning gold surface contaminated at process

- following ENIG or ENEPIG finishing

-

Applications

- cleaning gold surface such as ENIG. ENEPIG and soft gold on HDI, FPCB, BGA, FC-BGA etc.

Eco-friendly Flux Cleaner

-

Features

- Halogen-free cleaner

- Suitable flux cleaner for several SMT process

- No hazardous martials restricted by Korean Government and European Union

-

Line-up

수강정보

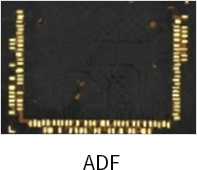

| Applications |

Base |

Types |

Product |

Surface tension |

Boiling point |

Working temperature |

Camera

module |

Aqueous

base |

Aqueous cleaner |

ADF |

33 dyne/cm |

>100℃ |

55 ~ 65℃ |

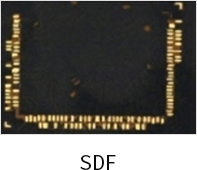

| Semi-aqueous cleaner |

SDF |

30 dyne/cm |

>100℃ |

55 ~ 65℃ |

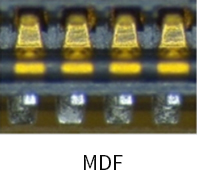

Normal

SMT |

Solvent

base |

High-temp, cleaner |

MDF |

20 dyne/cm |

>100℃ |

55 ~ 65℃ |

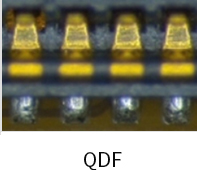

| Low-temp, cleaner |

QDF |

21 dyne/cm |

75 ~ 78℃ |

25 ~ 35℃ |

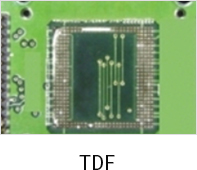

| Wave soldering |

Recyclable cleaner |

TDF |

20 dyne/cm |

81 ~ 85℃ |

75 ~ 85℃ |

HOME

HOME