Ultra-thin Copper Foil

- About 2um to 6um ultra-thin copper foil that becomes the raw material for EMI shielding and FCCL.

- The world’s first copper foil manufactured by electroless chemical copper plating process

HOME

HOMEElectronic Materials Our thin copper foil manufactured by using the world’s first electroless chemical copper plating process has versatile applications including EMI shielding, FCCL, and radiating film.

Ultra-thin Copper Foil

EMI Shielding Sheet

PET CCL

RTR Manufacturing Facility

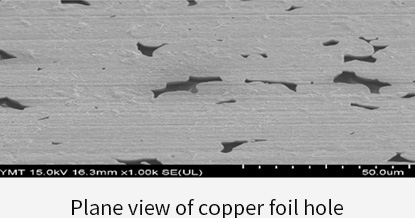

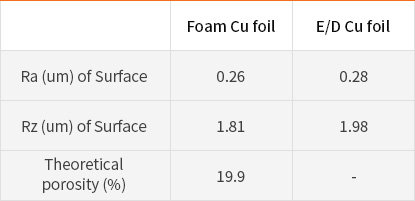

Foam thin copper foil for 5G high speed transmission EMI shielding, low roughness, and porosity

Shape

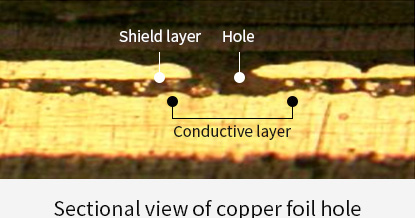

Characteristics of copper foil

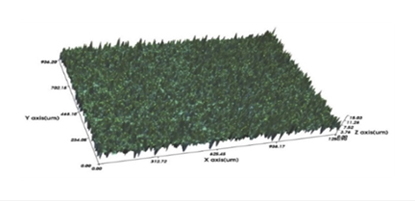

Nano-scan Image

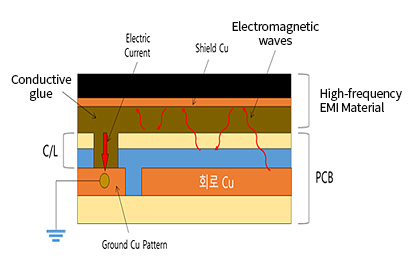

Overview of materials for high speed transmission EMI shielding

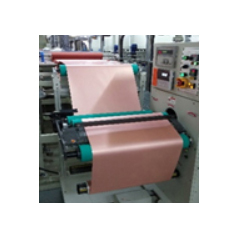

Roll To Roll Copper Plating

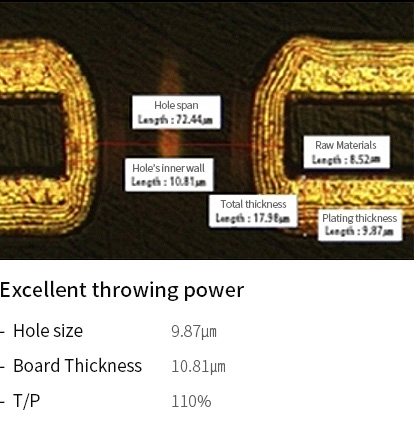

Cu plating uniformity

| Items | Min | Max | Average | |

|---|---|---|---|---|

| Raw Materials | Top | 8.1 | 8.5 | 8.3 |

| Bottom | 8.1 | 8.6 | 8.4 | |

| After plating | Top | 18.2 | 19.3 | 18.5 |

| Bottom | 18.2 | 19.5 | 18.5 |